Core Advantages

A stiffer boat performs better. As it moves through the water and cuts the waves, less energy is absorbed by hull flex, and more is translated into forward progress. Our proprietary lamination process not only produces strong boats, it creates extremely stiff hulls. Stiffness and strength are often related properties, but they are not the same thing. For a simple example, let's look at a bag of potato chips. The bag itself is typically made of a fairly strong plastic material, but it has almost no stiffness. The chips, while fairly fragile, have a much higher degree of horizontal stiffness. To carry a load, you want a bag made from strong material. But if you want to scoop up some onion dip, you'd choose the chips for stiffness, and a thicker chip would be better than a thin one.

The same holds true when building boats.The thicker the laminate, the stiffer it becomes, by a cubic factor. In layman's terms, that means a hull section twice as thick will be eight times as stiff. But thickness also adds weight, and that's where coring comes into the picture. Encapsulating a core material between inner and outer skins of fiberglass creates what is known as a sandwich laminate, which behaves much like a steel I-beam. Coring allows boat builders to reduce weight while increasing both strength and stiffness.

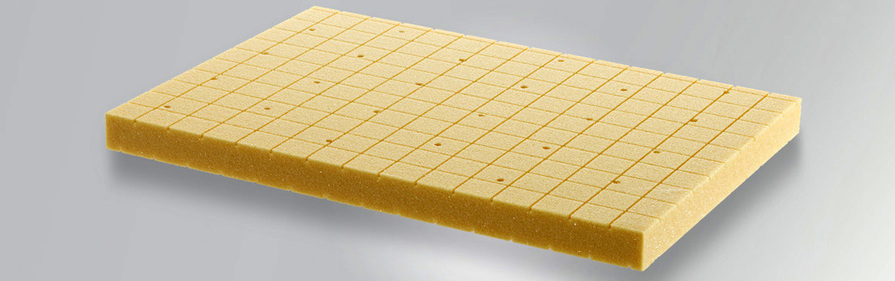

The materials used for coring include plywood, balsa wood, honeycomb composites and a range of foam materials. Through research, experience and experimentation we have decided that the best material to incorporate into the lamination schedules of high-performance fishing boats are high-density, closed-cell PVC foams. These materials offer the best combination of performance and longevity. When properly bonded to the outer layers of the lamination, a foam core will absorb and spread the slamming loads and stresses that performance hulls experience.

There are two additional advantages of a foam-cored hull. The coring provides a significant degree of sound deadening, resulting in a quieter ride in choppy conditions. The inherent buoyancy of the foam used by Mirage also makes our hulls unsinkable. In a worst case scenario, the boat would remain awash but afloat until help arrives.